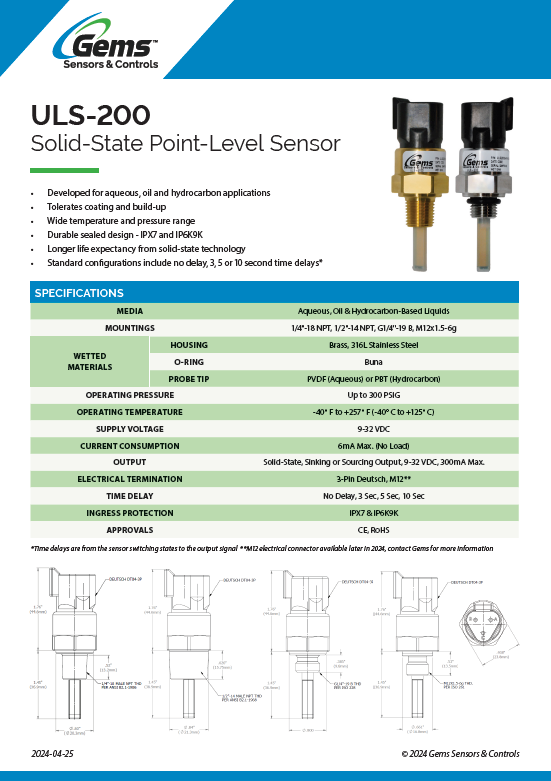

ULS-200 Solid-State Point-Level Sensor

PRODUCT DESCRIPTION:

The versatile ULS-200 is a solution for OEM applications. The sensor is compact, tolerates coating, and is rugged enough for mobile equipment in agricultural, construction, buses as well as power generation, semiconductor and HVAC applications.

FEATURED DOWNLOADS:

Features

- IPX7 & IP6K9K

- RoHS - CE

- Solid-State Output

- Sinking or Sourcing

- Wet or Dry Signal

- Resists Coating & Build-Up

- Water -Oil - Hydrocarbon-Based Liquids

- High Process Pressure to 300 PSIG

- Standard Configurations Include Choice of Time Delays

- Aerospace - Defense

- Aerospace - Environmental Control Unit

- City Buses, Luxury buses, Touring Buses

- City, Luxury, and Touring Buses

- Excavators

- Excavators, Earthmovers, Backhoe

- Fire Trucks, Ambulances, Vacuum Trucks

- Food & Beverage - Beverage dispensing

- Food & Beverage - Brewery

- Food & Beverage - Brewing Equipment

- Food & Beverage - Food Service Equipment

- Food & Beverage - Fryers

- Food & Beverage - Other

- Food & Beverage - Ovens

- Food & Beverage - Steam Cookers

- Food & Beverage - Systems Integrator- OEM- both

- Food & Beverage - Washers

- General Industry - Appliance

- General Industry - Car Wash Equipment

- General Industry - Chemical Metering/Injection

- General Industry - Cleaning Equipment

- General Industry - Compressors

- General Industry - Elevators

- General Industry - Fountains

- General Industry - Hydraulics

- General Industry - Laser Equipment

- General Industry - Machine Tool

- General Industry - Machinery

- General Industry - Motors

- General Industry - Other

- General Industry - Plasma Cutting

- General Industry - Plastics & Packaging

- General Industry - Printing - 3D

- General Industry - Printing Equipment

- General Industry - Purifiers

- General Industry - Skid Manufacturer

- General Industry - Tanks

- General Industry - Tanks - Specialty Chem

- General Industry - Test & Measurement

- General Industry - Welders

- Harvesters, Sprayers, Planters

- HVAC/R - Cooling

- HVAC/R - Cooling Towers

- HVAC/R - Evaporators

- HVAC/R - General HVAC

- HVAC/R - Heating/Condensate Systems

- HVAC/R - Humidifers

- HVAC/R - Other

- HVAC/R - Refrigeration

- HVAC/R - Warmers

- HVAC/R - Warrick

- Marine - Commercial - Ship Systems

- Marine - Commercial - Shipbuilder

- Marine - Commercial - Workboats

- Medical - Analytical Instruments

- Medical - Cooling

- Medical - Imaging

- Medical - Immunochemistry

- Medical - IVD

- Medical - Lab

- Medical - Laboratory & Testing

- Medical - Life Sciences

- Medical - Medical Lasers

- Medical - Other

- Medical - Radiology

- Medical - Renal Care / Dialysis

- Medical - Sterilization

- Medical - Washers

- Mining, Military Vehicles, Forestry

- OHV - Agricultural Equipment

- OHV - Construction Equipment

- OHV - Fertilizer

- OHV - Fire Trucks

- OHV - Forestry Equipment

- OHV - Highway Construction Equipment

- OHV - Industrial Equipment

- OHV - Lawn Equipment

- OHV - Material Handling

- OHV - Military Vehicles

- OHV - Mining Equipment

- OHV - Other

- OHV - Recreational Vehicles

- OHV - Refueling Trucks

- OHV - Specialty Equipment

- OHV - Street Sweepers

- Power Generation - Fuel Cell

- Power Generation - Generators

- Power Generation - Green Energy

- Power Generation - Other

- Power Generation - Turbines

- Power Generation - Wind-Motor

- Power Generation, Renewable Energy

- Process Industry - Chemical

- Process Industry - Other

- Process Industry - Process Tanks

- Process Industry - Pulp & Paper

- Process Industry - Textiles

- Semicon Equipment

- Semiconductor- Cooling

- Server Farm - Liquid Cooling

- Transportation - Buses

- Transportation - Commercial On-Road Vehicles

- Transportation - Engine Performance

- Transportation - Fire Trucks

- Transportation - Fuel - Level Monitoring

- Transportation - Other

- Transportation - Specialty Vehicles

- Transportation - Test & Measurement

- Water & Waste Water - Chemical Metering/Injection

- Water & Waste Water - Other

- Water & Waste Water - Point of Use

- Water & Waste Water - Pumps

The ULS-200 can sense aqueous, oil, and hydrocarbon liquids.

I have limited space. Will the ULS-200 work for me?

The ULS-200’s compact design, and less than 3.25” overall length fits in the smallest footprint making it great for mobile applications.

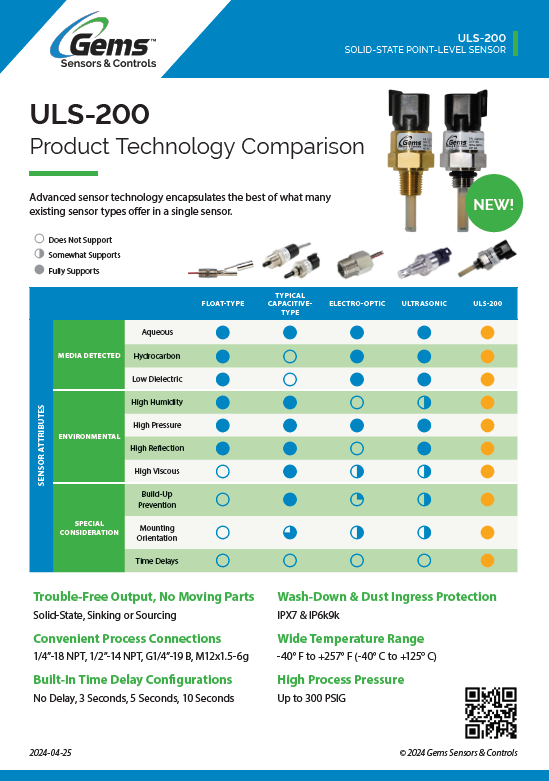

I use float-type, electro-optic, and ultrasonic sensors on my equipment. Which sensors can the ULS-200 replace?

Gems’ ULS-200 encapsulates the best of what existing sensor types offer in a single sensor technology. It was designed to work with a wide variety of media. It eliminates failure caused by moving parts. It works well in high viscous, high pressure, humid, and reflective applications. It does not rely on specific gravity and resists coating and build-up, eliminating many of the limitations and failures inherent to other sensing technologies.

How is the ULS-200 affected by coolant coating the sensor probe?

The PVDF or PBT sensing elements are both designed to resist coating and build-up due to the smooth surface material. How does the ULS-200 handle sloshing or turbulence?

The ULS-200 can be configured with a time delay on increasing level, decreasing level, or both. The sensor will not trigger as liquid present or as dry condition until after the configured delay has lapsed.

How is the ULS-200 better than my float level switch?

The float type level switches are susceptible to build-up and mechanical failure over time due to having moving parts. The switching is usually done with an internal reed switch. This is also at risk of failure from normal wear and electrical damage. The ULS-200 uses reliable solid state (no moving parts) electronic switching with an open collector.

What is an open collector output?

The open collector is an electronic solid-state switch with no moving parts. It works with DC power and basically toggles the current flow from the output signal wire to ground. It has a base, a collector, and an emitter. The sensor signal is always the base leg, and current is either allowed or blocked from collector to emitter with the presence of liquid (depending on the configuration).

Can the ULS-200 trigger a signal in either wet or dry condition?

The ULS-200 can be configured in the factory to signal when the sensor element is wet or dry with optional time delays and either a sinking or sourcing circuit.

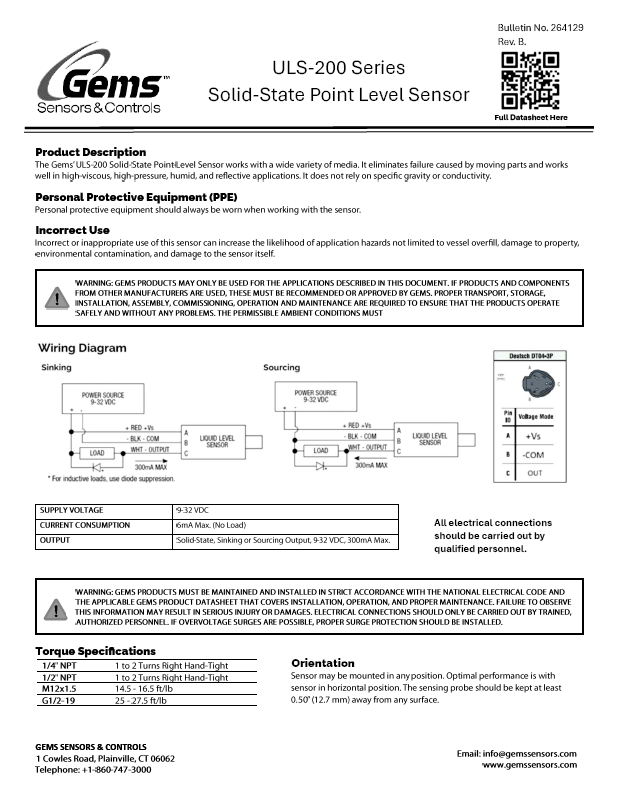

How do I choose between sinking or sourcing?

It all depends on how you wish to wire the sensing circuit. In a sinking configuration, current passes through the load first, through the output switch of the sensor second and lastly to ground. It is a transistor logic output that switches the DC ground, or negative, leg of the circuit. In a sourcing configuration, the load must be connected between the sensor output and the DC ground. With a sourcing sensor, your input voltage powers the load. It is a transistor logic output that switches the DC positive voltage. A sensor with a sourcing output switches the positive leg of the circuit.

Is the ULS-200 suitable for outdoor use?

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER